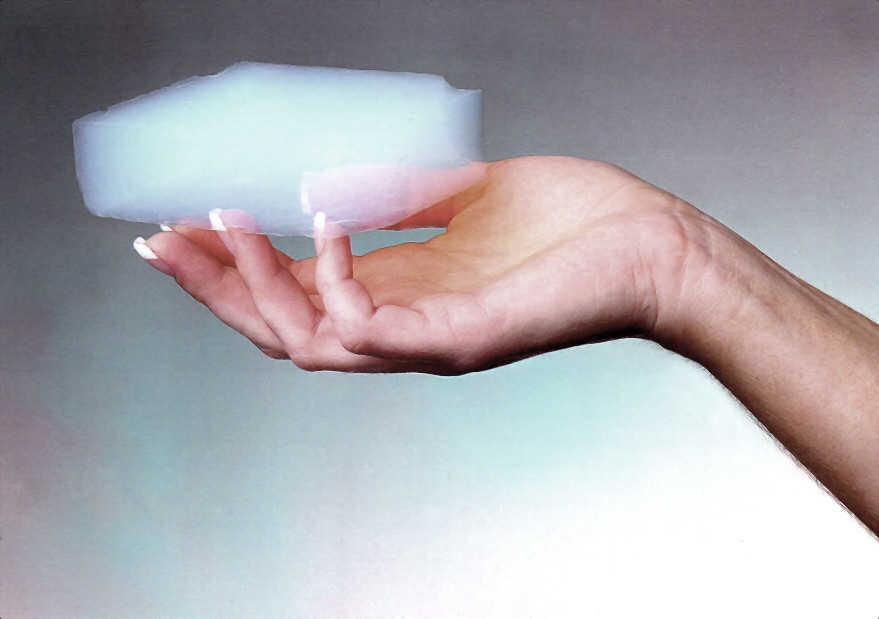

Aerogel, often dubbed "frozen smoke" or "blue smoke," is a remarkable material that has gained immense attention for its exceptional properties. It is considered the lightest solid on Earth, with astonishing insulating capabilities. In this blog post, we will delve into the world of aerogel, exploring its manufacturing process, applications across various industries, and the science behind its extraordinary properties.

What is Aerogel?

Aerogel is a synthetic porous material derived from a gel. It consists of a solid network of interconnected nanoparticles or polymers suspended within a gas, usually air. This unique composition results in a solid structure that is up to 99.8% air, making it extremely lightweight. Despite its minimal density, aerogel possesses remarkable thermal, acoustic, and electrical properties.

Manufacturing Process:

The production of aerogel involves a complex process known as supercritical drying. Here are the key steps involved:

-

Gel Formation:

The process begins by creating a gel, typically using a sol-gel method. This involves combining a liquid precursor, such as a metal oxide or a polymer, with a solvent. The precursor forms a stable gel network throughout the liquid. -

Solvent Replacement:

The gel is then subjected to a process called solvent exchange. The solvent is gradually removed from the gel and replaced with a liquid, such as liquid carbon dioxide (CO2). This step is crucial to preserve the structural integrity of the gel. -

Supercritical Drying:

The liquid within the gel is subjected to supercritical conditions. Supercritical drying involves exposing the gel to high temperatures and pressures, surpassing the critical point of the liquid (the temperature and pressure at which it transitions into a supercritical fluid). As the liquid becomes supercritical, it transforms into a gas without passing through the liquid phase, leaving behind a solid structure with the original gel network intact. -

Structural Reinforcement:

To enhance the mechanical strength of aerogel, additional steps like cross-linking or reinforcement with other materials may be employed.

Applications of Aerogel:

Aerogel's exceptional properties make it an invaluable material across a wide range of industries. Some notable applications include:

-

Thermal Insulation:

Aerogel possesses an incredibly low thermal conductivity, making it an outstanding insulating material. It is used in the construction industry to insulate buildings, pipelines, and appliances, resulting in improved energy efficiency. -

Aerospace and Defense:

Due to its lightweight nature, aerogel finds applications in aerospace as insulation for spacecraft, protecting against extreme temperatures during re-entry. It is also used in military equipment, such as thermal protective clothing and lightweight armor. -

Environmental Protection:

Aerogel is utilized in oil and chemical spill clean-up operations. Its hydrophobic properties allow it to absorb and contain hazardous substances effectively. -

Energy Storage:

Aerogel's high porosity and large surface area make it an ideal candidate for energy storage devices like supercapacitors and batteries. It enhances their performance by facilitating faster charging and discharging. -

Electronics and Sensors:

The excellent electrical properties of aerogel enable its application in electronic devices, such as sensors, catalysts, and energy-efficient batteries.

The Science behind Aerogel's Properties:

Aerogel owes its extraordinary properties to its unique nanostructure. The nanoporous network of interconnected particles creates an extremely large surface area, providing superior insulation and adsorption capabilities. The structure also scatters light, resulting in its translucent appearance.

Furthermore, the nanostructure of aerogel traps gas molecules within its pores, hindering the transfer of heat, sound, and electricity. This property makes aerogel an excellent thermal insulator, sound absorber, and electrical insulator.

The remarkable properties of aerogel can be attributed to two key factors:

-

Porosity and Surface Area:

Aerogel's nanostructure consists of a three-dimensional network of interconnected particles, creating a highly porous material. The pores in aerogel can range from a few nanometers to a few micrometers in size. This extensive porosity provides a large surface area per unit volume, enabling aerogel to interact with gases and liquids more effectively. The increased surface area enhances its thermal insulation and adsorption capabilities. -

Low Density:

Aerogel is composed mostly of air, with a solid framework that is highly porous. As a result, aerogel exhibits an extremely low density, often less than 0.1 g/cm³. This characteristic makes it one of the lightest solid materials known to humankind. Despite its low density, aerogel exhibits impressive mechanical strength and rigidity, allowing it to withstand significant compressive forces.

The science behind aerogel's exceptional properties can be understood through its thermal conductivity. Thermal conductivity is a measure of how easily heat can pass through a material. Aerogel possesses an exceptionally low thermal conductivity due to multiple factors:

-

Solid Structure:

Although aerogel is composed primarily of air, the solid framework of interconnected particles plays a crucial role in reducing thermal conductivity. Heat transfer occurs through solid-to-solid contact between particles. The intricate structure of aerogel hinders the transmission of heat by limiting the contact points between particles. -

Nanoporous Network:

The nanostructure of aerogel contains a vast number of small pores. These pores act as barriers to heat transfer by inhibiting the movement of gas molecules. The confined gas within the nanopores exhibits low thermal conductivity, resulting in the overall reduction of heat transfer through the material. -

Radiative Heat Transfer:

Aerogel's translucent appearance is due to its ability to scatter and absorb light. This property reduces radiative heat transfer, which is the transfer of heat through electromagnetic waves. By impeding the passage of infrared radiation, aerogel minimizes heat transfer through this mechanism.

In summary, aerogel's remarkable properties, including its low density, excellent thermal insulation, and sound-absorbing capabilities, are a result of its unique nanostructure. The combination of porosity, large surface area, and solid framework contribute to its exceptional performance across various applications.

Conclusion: Aerogel is a fascinating material that continues to captivate scientists, engineers, and researchers. Its exceptional properties, including its lightweight nature, outstanding thermal insulation, and remarkable sound absorption abilities, make it a versatile material with numerous applications. As researchers explore new avenues and advancements in aerogel technology, we can expect to witness its widespread adoption in fields ranging from construction and aerospace to energy storage and environmental protection. Aerogel's potential to revolutionize industries and improve the efficiency of existing technologies is truly awe-inspiring, paving the way for a more sustainable and innovative future.

Discover More

Most Viewed

Christmas is a season of joy, love, and traditions. And what better way to get into the holiday spirit than through timeless carols? These musical gems have been bringing people together for generations. Here’s our ranked list of the Top 10 Christmas Caro…

Read More